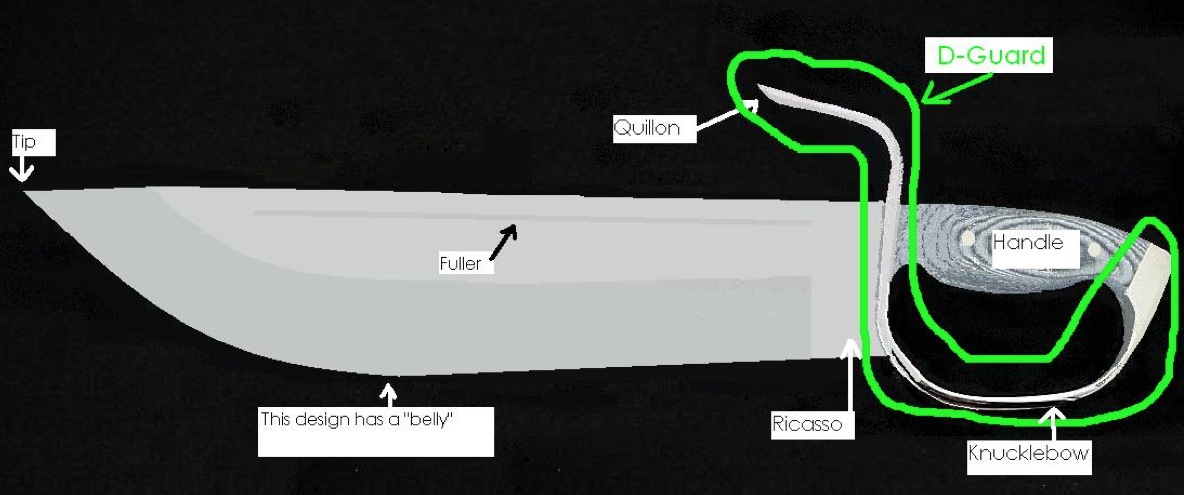

We will now take a look at the D-Guard (and its components the Quillon and Knuckle-Bow). This is what will allow you to trap weapons, flip your sword, protect your hand, and help you block incoming blows. For the most part the D-Guard is what makes a butterfly sword a butterfly sword. Let’s take a closer look.

D-Guard, Quillon, and Knuckle-Bow

D-Guard

D-Guard: A cross-guard with a quillon on top and a knuckle protector that runs to the pommel on bottom.

The D Guard is a major distinguishing characteristic of Hudiedao-style knives. It gives the weapon significant additional capabilities. Half handles are another key feature historically, but you also see them on Jian and the D Guard can add more functionality.

D Guards function best when optimized for a specific use. Very few custom knife makers, sword forges or manufacturers truly understand D Guards. The D Guard is the reason many highly talented U.S. custom knife makers decline to produce Butterfly Swords.

Trappers, Hybrids, Flippers

Flipping vs. Trapping D Guard: Refers to the Quillon and if it is made for flipping or trapping.

Flipping the butterfly sword to a reverse grip offers additional techniques especially suited to close-in fighting. One can punch with the pommel, cover or block with an arm of steel, forward elbow using your body mass to create a powerful slice when the opponent is too close to build up speed for a forward grip technique and if the blade extends past your elbow (non-Wing Chun styles) stab with a reverse elbow.

Although the Cantonese Hung Gar Butterfly Sword form does not flip the knives from the forward to a reverse grip, Ha Say Fu Hung Gar forms and Shaolin do. A number of individual Wing Chun practitioners also like the option of flipping the knives.

To make flipping viable, the D Guard needs adequate room between the quillon and spine of the blade to fit the webbing of the hand between the thumb and index finger (referred to here as the mouth of the hand). The quillon should also ride forward enough to add safety during the flipping process. The best pure flipping designs are inherently least protective of the hand and more dangerous for inexpert users attempting to cover or block with post of the quillon.

Some lineages trap and secure an opponent’s weapon between the quillon and the spine of the blade. There is always a trade-off between flipping ability and trapping ability. The more you can do of one, the less you can do of another. The quillon on a trapper needs to be just far enough from the blade to fit the opponent’s weapon and as parallel as possible to maximize trapping effectiveness. If the only weapon accommodated is a blade there need be very little room between the quillon and spine. If the intention is to also trap a staff more room is required but the optimal distance remains insufficient to accommodate the hand as needed for flipping.

EWC’s trapping quillons are very effective and so can easily “mess up” the opposing weapon. In between the two extremes of trapping only and flipping only is a hybrid quillon capable of doing both but not perfect for either.

Certain schools that train weapon vs. weapon regard trapping as too slow and dangerous. Many of the War Era knives have a quillon that angles away from the blade for just a short distance and is incapable of trapping but especially well adapted to covering with the quillon (i.e., better at blocking).

The discussion above makes D Guard design sound easy but it is anything but. Achieving the objectives in the most optimal manner possible is intrinsically complex and must be integrated with all other aspects of the sword design. It takes great expertise to create a Butterfly Sword with geometry that works well in both a forward and reverse grip and can naturally flip back and forth smoothly. And while many vendors offer trapping designs, there are optimization issues there too.

3D vs. Steel Strip

Most Kung Fu styles and Wing Chun lineages prefer a solid three-dimensional D Guard. Done right this method of construction can reduce the chance of catastrophic weapon failure during quillon based interception and trapping techniques or when the knuckle bow or pommel are used for bashing or punching.

An alternative method of construction is the metal strip. Nearly all brass or steel strip D Guards are made that way to reduce manufacturing costs and actually as lacking in merit as they look.

Certain Moy Yat lineages prefer a steel strip D guard with a sophisticated flexible quillon specifically designed to facilitate trapping. These sticky quillons can be tailored to catch staffs and blades, or more narrowly aimed at just blades. EWC’s Moy Yat stabbers feature a flexible quillon able to trap blades and poles

Knuckle Bow

Knuckle Bow: The curved portion of a sword guard that covers the fingers.

The knuckle bow part of the D Guard protects the hand. While the knuckle bow of a D Guard must connect to the pommel or there would be no “D” some knuckle bows stop short.[1]

War Era knuckle bows had a rectangular cross-cut profile. There are a few modern limited production Butterfly Swords with historical replica D Guards that exhibit that profile but martial artists greatly prefer modern designs focused on the needs of their style and lineage.

The higher quality modern style full handle sword knuckle bows generally have a cross-cut profile that looks like an oval or has a curved exterior to reduce weight. The better modern half handle sword knuckle bows are rounded on the outside but left at right angles on the inside with the edges sanded.

There are a variety of knuckle bow shapes, each with different qualities. A perfectly symmetric “D” rounding, with the flat area in between the curved corners, can be used to minimize surplus space between the knuckles and the knuckle bow, reducing the width of the weapon. Non-flipping lineages prefer the least hand space necessary, but if the sword will be flipped a modest safety margin is prudent. If extra space is added the front corner becomes more prominent and possibly better able to catch a weapon that has slipped down the cutting edge; of course the weapon profile increases. Given that the rear of a fist is smaller than its front, some knuckle bows skew towards the pommel in accordance with the profile of a fist, eliminating surplus space inherent with a perfectly symmetric design.

Rounding out the knuckle bow to eliminate any straight runs increases its structural integrity so it is better capable of surviving an impact when covering, blocking or bashing with any portion. This can be done on a symmetric or skewed basis, and with minimal or surplus space. Some knife designs add surplus space to permit a straight run of D Guard adjacent to the blade where the blade must be attached for easier construction. The best way to accommodate a minimal space rounded knuckle bow is to continue rounding the front of the knuckle bow past the Choil. That means the piece of steel used to make the blade must be longer and additional difficulty (read expense) when joining the blade to the D Guard and polishing. EWC’s Flagship Line offers the highest quality rounded knuckle bow available.

The knuckle bow on War Era Hudiedao was thinnest where it met the rear of the handle. That is also where the tang was peened, making that spot structurally weak and a risky portion of the sword to use for punching or bashing. A Butterfly Sword can be designed to align the butt portion of the D Guard with the forearm for strong punching while holding the knife with a reverse grip. If the tang is peened, which is typical of hidden tang construction, impact may weaken the peen. If there is a welded or laterally pinned full tang the impact is less likely to harm the sword.

If the tang is peened, it is possible to round and thicken the rear of the knuckle bow so a different area can be used as the impact surface. The rear of the knuckle bow on the Long Stabbers is rounded like on Ip Man’s knives causing a section beneath the peen to be the primary impact point for punches or bashes with the rear of the knife.

The prong on the Tomb Warrior line square D Guard can be used to help catch an opponent’s blade slipping off the D Guard or as an offensive impact concentration point.

D-Guard Material

D Guards were traditionally made of brass alloy, bronze, wrought iron or steel. Today they are made from brass or steel. Tough steel is stronger than brass, but substantially increases the difficulty and cost of construction so much that lesser steels are commonly used. Steel provides the additional option of welding the tang to the D Guard, a process we cannot do with a brass D Guard.

The best steel for knife bolsters is AISI 304 stainless steel. It is extraordinarily durable, takes a great polish and highly resistant to corrosion. It is so difficult to work that nearly all of the individuals who make expensive custom Western knives cut a corner and use AISI 416 instead. In 2010 EWC determined AISI 304 was the best material for three-dimensional D Guards and began to use it routinely.

Three-dimensional D Guards are typically made by casting, a solution proven adequate in combat and used by both Asian manufacturers and custom Butterfly Sword makers. They can also be made by bending rod stock, as is the case with Ip Man’s choppers, bending and grinding bar stock, or cutting then grinding thick plate.

The processes that produce the absolute best D Guards are hammer forging and hot drop forging. Like hammer forging, hot drop forging realigns the grain of the steel resulting in improved strength characteristics. Both methods are more expensive than simple casting, with hammer forging of stainless steels a rare skill. Although there are some inexpensive carbon steels that smiths could work by hand to make a strong D Guard, carbon steel is a poor choice because it must be kept oiled in between use and cleaned every time it comes in contact with skin. EWC uses hot drop forged AISI 304 stainless steel D Guards on its Flagship Line.

Surface pitting is a problem inherent with castings and forgings, especially factory made D Guards. One of the methods Iron Man Steel uses to minimize these potentially annoying blemishes is to intentionally make molds and dies slightly larger than the final shape so blemishes that occur can often be ground out. The additional grinding is an added labor expense. The forge inspects at several stages in an effort to weed out D Guards that will never make the cut as early in the process as possible and reduce the cost of the scrapped swords. The alternative for a reputable forge is to make more precise molds then reject a higher percentage of the rough product. Ethically challenged manufacturers have a financial incentive to use the less labor intensive more precise molds and retain D Guards that should have been rejected.

EWC classifies swords as cosmetic seconds if the pitting reaches fairly tight threshold, then sells them for a lower price. These seconds are an outstanding value since an EWC second is likely to be far nicer than a competitor’s first. They sell rapidly.

A lot of D Guards are made from cast brass, which is easy to cast and work. While nowhere near as tough as AISI 304, brass saw frequent historical use with Butterfly Knives whereas AISI 304 stainless steel did not. Some Asians based designers dislike brass because it smells. The smell can rub off onto your hands.

Brass has a beautiful golden hue when freshly polished. Pure brass technically cannot rust but it gets dull over time and the oxidation of the copper looks a lot like rust. It is probable that the D Guard on purchased swords that were sitting in a warehouse will lack the shine of the D Guard in the advertisement. There are several easy methods to restore the original luster. One preventative solution is to lacquer the brass.

Another is to use gold-plating but care is required during the production process. It is not cheap to do well. Gold plating really adds a touch of class, whether your D Guard is brass or high grade stainless steel. EWC offers this option only on sharpened swords sold for display purposes. They should not be used for training since the plating can wear off with stress and ordinary use. Lacquer and other coatings can also wear off.

This video is Part 7 of 10 on Choosing Butterfly Swords by Jeffrey Modell. This video goes along with the blog article, but does not follow the exact same order of topics. We apologize that the AUDIO is OUT OF SYNC. This is the way the camera filmed the footage, so there is little we can do about it (simple aligning will not work). We hope you get some benefit, regardless:

[youtube]http://youtu.be/mvq81SJeZQM[/youtube]

Nice job! You are quickly becoming a sword expert! Ready for more? Click here for Sword Balance Knowledge

[1] According to Dr. Yang, Jwing-Ming the Chinese short sword with an “S” shaped guard (quillon, cross-guard and knuckle bow that does not connect to the pommel) was still a Hudiedao but also referred to as a Son-Mother Saber (Zo-Mu Dao), Hand Protection Saber (Hu Shou Dao), or Wrap Elbow Saber (Bao Zhou Dao). Dr. Yang, Jwing-Ming’s Ancient Chinese Weapons A Martial Artists Guide p.77 (YMAA Publication Center, ©1999 Yan, Jwing-Ming).

One thought on “Choosing Wing Chun Butterfly Swords – Part 6 – D-Guards”