We will now take a look at Tangs, Handle Types, Alignment, Ergonomics, and Handle Materials. These are critical aspects of a sword. The tang can literally be the difference between life and death if you are using the sword for combat – or even training with contact. The handle types and ergonomics can really make a difference in your comfort and power. Let’s learn more.

Tangs, Handle Types, Alignment, Ergonomics, & Handle Materials

Tangs

Tang: The metal blade piece that extends into or connects to the handle.

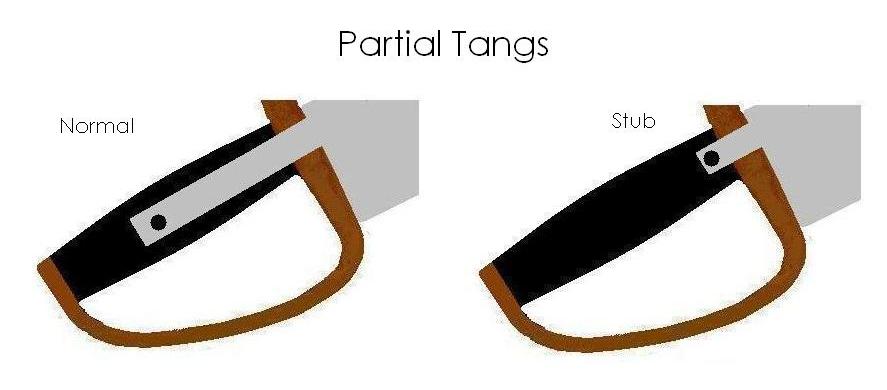

The blade is attached to the D Guard and handles with a tang. There are a number of conflicting definitions for tang-related terminology. “Full tang” is sometimes defined as tang that runs through the full length of the handle grip, with a “partial tang” being a tang that runs some fraction thereof. Top quality Butterfly Swords have a tang that runs from the blade into the rear of the D Guard. Some of the mass production mid-grade knives have a really stubby partial tang that we can tell you from experience should not inspire confidence.

U.S. custom knife makers generally define a full tang as a tang that extends the full length and width of the handle so the metal edges are exposed ice cream sandwich-style. We will use that definition going forward.

Full Tang: A tang that runs the full length of the swords and is visible between the handle scales. You can see the part of the blade steel that runs through the handle all the way to the butt, like the center of an ice cream sandwich. D-Guard is attached with pins or welding.

The modern full tang is the strongest tang. Although the tang might be drilled to adjust weight, seeing its outline size is a good indication you are getting what you are paying for when you are unsure of the manufacturer’s reputation. The downside is that the tang edge is exposed to corrosive skin oils. This is of little import with stainless steels and D-2 (just clean normally), but there are maintenance implications for carbon steel. It is also a dirty little knife maker’s secret that handle scales eventually shrink so the hand can feel the tang’s edges.

The modern full tang is the strongest tang. Although the tang might be drilled to adjust weight, seeing its outline size is a good indication you are getting what you are paying for when you are unsure of the manufacturer’s reputation. The downside is that the tang edge is exposed to corrosive skin oils. This is of little import with stainless steels and D-2 (just clean normally), but there are maintenance implications for carbon steel. It is also a dirty little knife maker’s secret that handle scales eventually shrink so the hand can feel the tang’s edges.

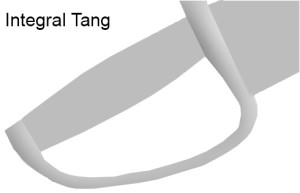

Integral Tang: A blade, tang and D-Guard made from the same piece of steel.

The integral tang is one that is made from the same piece of steel as the D Guard and blade. It is made by hammer and anvil or what is called “hot-drop forging, where molten steel is slammed into a mold at a high-pressure. It is the same way hammers and other tools are made.

The integral tang is one that is made from the same piece of steel as the D Guard and blade. It is made by hammer and anvil or what is called “hot-drop forging, where molten steel is slammed into a mold at a high-pressure. It is the same way hammers and other tools are made.

One advantage is that the sword is one solid piece of steel so the blade and D Guard cannot loosen. Also, the steel becomes stronger due to alignment of the crystalline structure of the steel.

There are several disadvantages. The cost of hammer and anvil forging is shocking. The cost of hot drop forging is high and it frequently leaves some very small black pitting marks on the sword that cannot be polished out cost effectively. The D-Guard must be made of same type of steel as blade so if blade is carbon steel, then the D Guard will also be high maintenance.

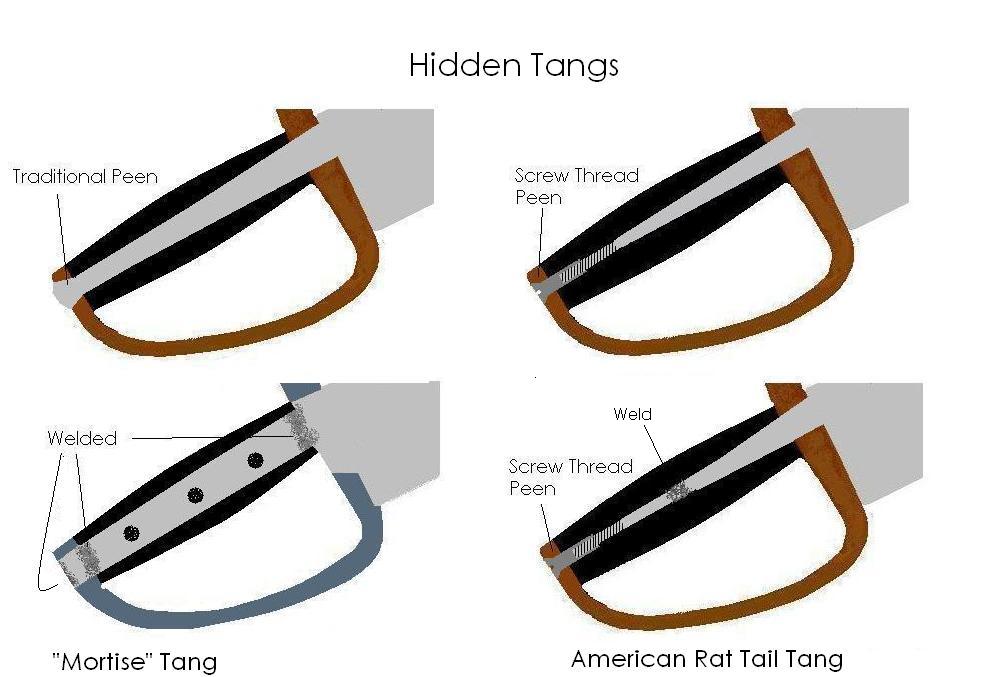

Hidden Tang (Full or Partial): A tang completely hidden within the handle material. A full hidden tang properly welded or peened to the base of the d-guard is usually very strong. A partial tang is not as strong as a tang that runs from end to end.

Historical Hudiedao used a narrow tang hidden entirely within the handle. It is a combat-proven design. From a designer’s perspective, the hidden tang allows for a lighter knife, prevents oils from the hand from touching tang steel, permits the use of a single block of wood to carve a decorative and highly shaped handle, and offers some extra decorative options using spacers of different colors or materials. You just glue the spacers in order on your block of material prior to carving the handle. It is a lot tougher decorating a full tang knife handle. Plus, you never have to worry about feeling the tang with your hand after handle shrinkage.

A hidden tang can be made so wide that it is impossible to drill and carve a slot down the handle to slide the tang in. Instead two scales, each with an impression indent carved for the tang, are joined around the tang. Some knife makers refer to this kind of wide hidden tang as a mortise tang but it is actually a mortised grip.

On the downside, because the tang is hidden you cannot see what is going on inside the handle. The quality can range from good to horrific and the buyer cannot see what is going on… and many more things can go wrong than with a full tang. There are many mass produced Butterfly Swords you would not use if you knew what it looked like on the inside. There is usually some space when a hidden tang is fitted through a cavity in a solid block handle. That space creates a risk that the tang will move and loosen the peen or break the weld. It can even happen to luxury grade War Era swords. On our Long Stabbers Iron Man Steel did a superior peening job, slotted the base of the blade into the D Guard and filled the cavity between the tang and the handle with resin to add support to the tang. The resin also augments the strength of the tang and helps the entire sword feel solid.

“Rat Tail” Tang: Partial tang welded to a threaded cylinder that is screwed at the pommel.

In most of the world a “stick tang” or “rat tail tang” is a narrow tang (it looks like a rat’s tail). It is a species of hidden tang. Historical swords of all kinds mostly used a narrow tang. Done right it is not only light but so strong the blade is more likely to fail than the tang.

The term “rat tail tang” is commonly used in the U.S. to refer to a small diameter rod or bar welded on to a normal tang. You will even see low quality Butterfly Swords with the rod welded to a tang that barely goes through the D Guard or even welded to the base of the blade. With the wrong steel, an insufficient diameter, or a poor weld, the extension or the weld is prone to break. You tend to see a lot of shoddy rat tail tangs on inexpensive Chinese swords, including “razor sharp” Jian. Properly constructed – with a thick blade, a soft quality steel stick just as thick, and a solid weld – an attached rat tail can be quite adequate.

TIP: A razor sharp sword with a weak tang is definitely a wall hanger.

Handle Alignment

Handle Alignment: Relationship between the point on the handle that will be covered by the center of the closed hand around the grip and the tip of the blade.

Locating the handle on an axis with the tip maximizes control over the blade and improves thrusting. The Jian-style handle on War Era knives was near universally centered in the base of the blade and aligned with the tip. The blades on most War Era knives were so narrow, however, that the handle would not fit anywhere else. There are more places to fit the handle on wider blades.

The sword’s primary use dictates the best location of the handle relative to the blade. For thrusting, it should be aligned with the pointy tip. For percussive impact against armor, the handle should be centered on the blade. For chopping and slashing, it should be aligned near the spine to produce better, more effective blows. Spine alignment of the handle facilitates a reverse grip. Affixing the handle away from the spine makes it far more difficult to hold the knife properly in a reverse grip. The intended uses of the knife should dictate the optimal handle alignment. Jeffrey Modell, History and Design of Butterfly Swords, Kung Fu Tai Chi magazine p.60 (April 2010).

Many modern mass production butterfly swords have handles in the middle of the blades out of alignment with the tip. In 99% of the cases this is completely wrong and functionally incorrect (you don’t see a lot of folks training to down armored opponents these days), the product of ignorant or uncaring manufacturers.

Since modern Wing Chun is heavily dependent on slicing and chopping, the best place for the handle for most lineages is by the spine to be close to the tip rather than centered on the blade. Lineages that emphasize stabbing should insist on tip alignment whether the tip is at the spine or lower.

TIP: The most obvious design error is a misaligned handle.

Handle Type

Handle Type: Refers to if the swords have full handles, slim line full handles, or 2-in-1 handles (i.e., half handles).

The handle needs to facilitate retention and manipulation of the sword and the projection of force. That means sensible, comfortable and solid.

Full Handles

Full handles are the most comfortable type. These days having a better grip on the knife during training and combat is more important than a quick single-handed draw and holding both swords in one hand. Full handles also offer the greatest control over the sword and create less fatigue during extended use. The net result is fewer training accidents. The main downside is awkwardness and potential danger at the beginning of forms that require holding both knives in one hand if the full handles are too wide to be held safely in one hand. We design our full handles to be comfortable but not too thick for most individuals hold both in a single hand.

Full handles are the most comfortable type. These days having a better grip on the knife during training and combat is more important than a quick single-handed draw and holding both swords in one hand. Full handles also offer the greatest control over the sword and create less fatigue during extended use. The net result is fewer training accidents. The main downside is awkwardness and potential danger at the beginning of forms that require holding both knives in one hand if the full handles are too wide to be held safely in one hand. We design our full handles to be comfortable but not too thick for most individuals hold both in a single hand.

Slim Line Full Handles

Modern offerings also include really slim full handles. They are pretty much in between full handles for comfort and 2-in-1 handles for ease of single handed use, but can fit in a single sheath. Design and selection of materials is especially important with slim line handles as done incorrectly they produce rapid hand fatigue as you are forced to constantly apply extra pressure to assure a firm grip. EWC only makes these by request since its line of true full handled BJD are a superior option.

Modern offerings also include really slim full handles. They are pretty much in between full handles for comfort and 2-in-1 handles for ease of single handed use, but can fit in a single sheath. Design and selection of materials is especially important with slim line handles as done incorrectly they produce rapid hand fatigue as you are forced to constantly apply extra pressure to assure a firm grip. EWC only makes these by request since its line of true full handled BJD are a superior option.

2-in-1 Handles

Most antique Hudiedao had a Jian-type straight handle, typically 2-in-1, but there are also full handles out there. There is a semantic debate whether a pair of antique full handled knives could truly be called “Butterfly Swords” – and many of the full handle versions were used as a single in conjunction with a shield — but the modern answer is a resounding yes.

Most antique Hudiedao had a Jian-type straight handle, typically 2-in-1, but there are also full handles out there. There is a semantic debate whether a pair of antique full handled knives could truly be called “Butterfly Swords” – and many of the full handle versions were used as a single in conjunction with a shield — but the modern answer is a resounding yes.

Two-in-one handles are designed to be used as a pair. The inside of each handle is flat and the outside rounded such that each knife basically has half a full handle. Consequently the two swords can be stored in a single sheath, drawn with one hand from that sheath, held comfortably in a single hand, used as though they were a single sword (at least theoretically) and spread dramatically in front of onlookers who did not realize there were two knives. Many martial arts Butterfly Sword forms require both knives to be held in a single hand during the opening sequence.

A lot of modern 2-in-1 handles have wrapped brass edges, exposed brass edges or wood edges so sharp that they are very uncomfortable. The common work around is to wrap tape around the handles. Too many martial artists have had a bad experience with poorly constructed, ill-designed modern half-handled BJD.

TIP: If you aren’t confident a maker’s 2-in-1 handles are comfortable, don’t buy.

The problems are the result of corner cutting, not a flaw in the concept. The War Era antique Hudiedao photographed for this article (below) has a wood handle that has sanded rather than sharp edges. The EWC Tomb Raider line 2-in-1 handles were carefully designed with this in mind (black handle photo above left). Good 2-in-handles are fine for extended use though not quite as comfortable as full handles.

Sheath Systems from a Handle Perspective

divider for the blades, but not the handles (to facilitate 1 handed draws).

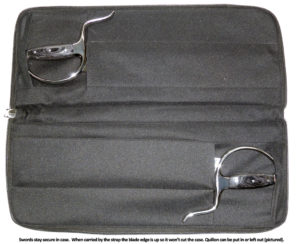

Traditional 2-in-1 knives were carried in a single leather sheath. The belt loop (if there was one) was beneath the mouth rather than rising up behind the handle Western style. Southern martial artists could tuck sheathed shorter knives into their pants using the quillon and conceal them with a jacket, hide them inside a Lion Dance troop’s lion head and strapped to the side of the drums in case of altercations between rival schools, or tuck them into a boot. While this single sheath design is fine for a working knife, if your BJD are gloss finish they can scratch each other in a highly noticeable fashion while going in and out of the traditional design sheath. That’s why EWC added an additional panel between the two blades in their 2-in-1 sheath designs. Also be aware that whenever two knives are held in a single hand or sheathed side-by-side, the handles rub together and, if made of hard material, scratch (though you may not notice it).

EWC has a specially designed nylon double sheath that will accommodate many of its blunt full handled BJD (but not on all models a single-handed draw). Nylon is a better covering material for BJD than leather because the tanning acids and vapor associated with leather promote corrosion. However, a sharp cutting edge will rapidly shred a ballistic nylon sheath and you need to exercise care inserting pointy knives into nylon sheaths lest the point stick or edge slice through (perhaps even into you).

EWC also offers the best nylon BJD carry case on the market with its Flagship Line and for sale separately. Practitioners might also wish to consider using an inexpensive Sai case, though the zippers do break on their own and a stabber could slide around until the point impales a zippered side.

Be cautious placing “sharps” in even an EWC carry case. If you do so try to face the cutting edge up to reduce the chances of unknowingly slicing the pocket. If the knife manages to go through the pocket, it still needs to penetrate the zipper to cause mischief.

A downside of many true full handled BJD is the common need for two sheaths. You will likely to receive two Western-style leather sheaths for the same side. In the U.S., long bowie knives were carried in a leather sheath with a metal stud on the outside a few inches beneath the mouth. The bowie knife’s sheath would be slipped inside a belt with the stud preventing it from falling out, and then a shirt or jacket used to cover the knife. For a pair of sharp full handled Butterfly Swords we recommend two mirror image sheaths made of heavy leather, one for the right side and one for the left.

Handle Ergonomics/Shape

Ergonomics: The science of design to maximize productivity by minimizing fatigue and discomfort.

Handle Shape: How the handle is shaped.

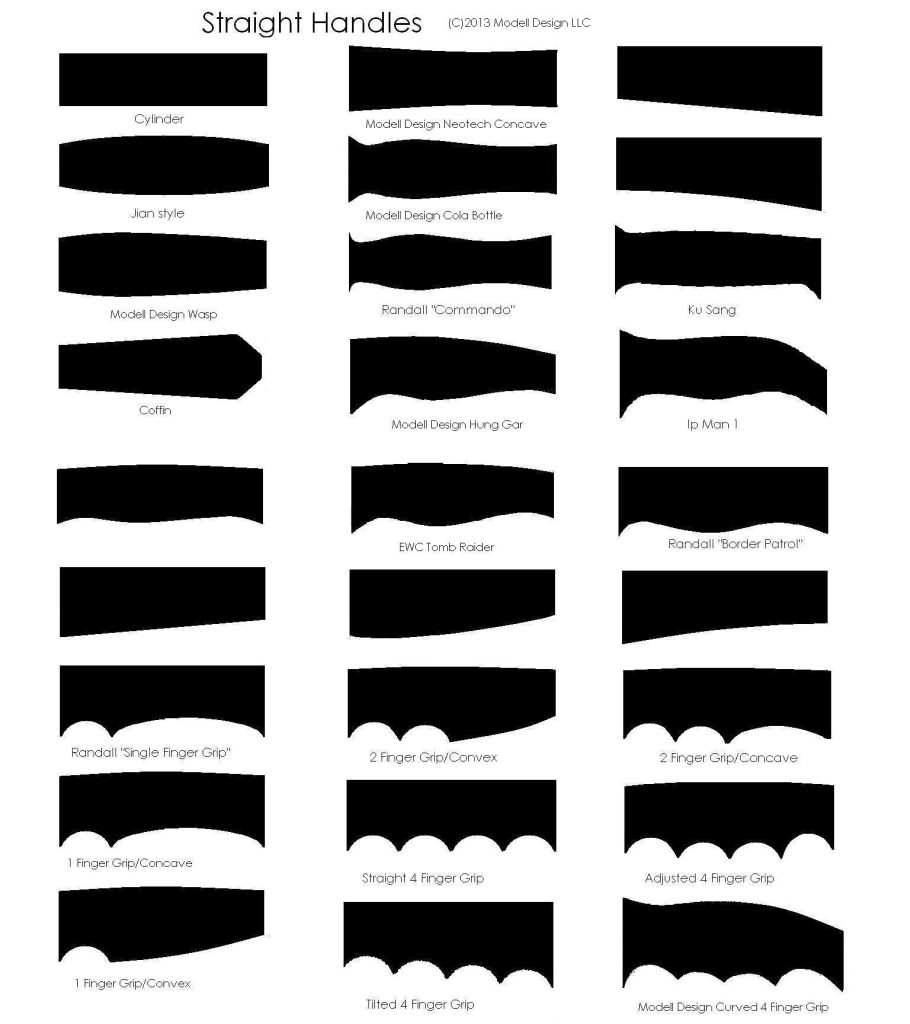

Handles should be ergonomically designed to be comfortable and reduce the odds of slippage. Straight handled Hudiedao were the most common historically and remain so today. Many modern martial artists prefer them because they were trained on straight handles or have certain techniques they prefer executing with a straight handle.

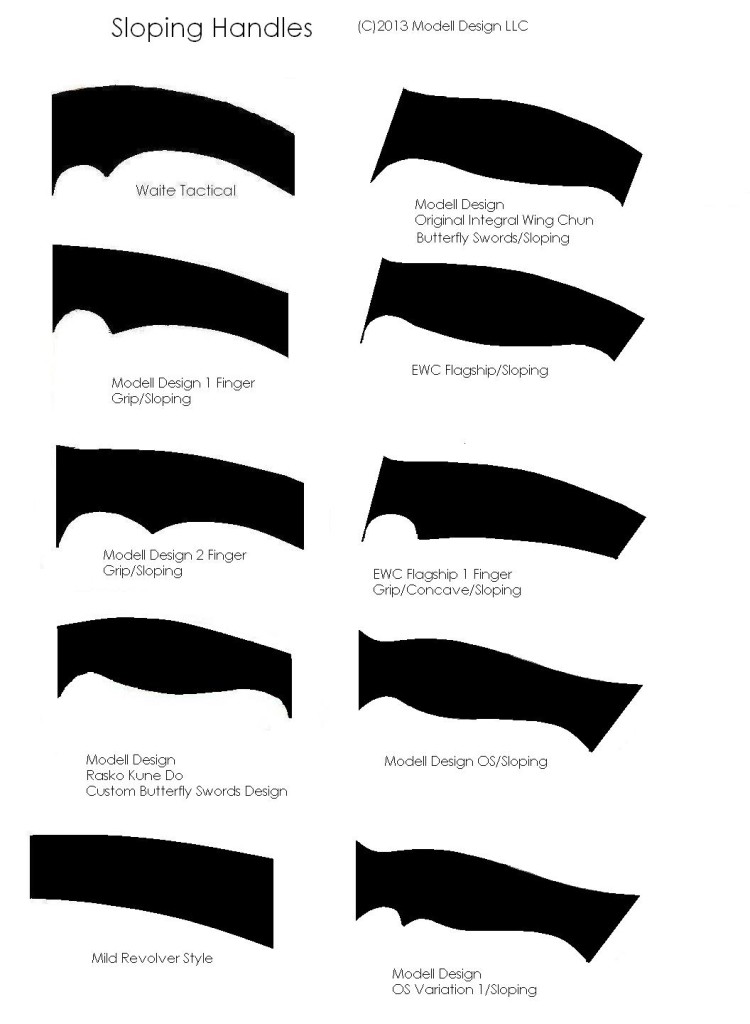

Modern Western knife makers have come up with innumerable handle tweaks, some of which are actually functional. These include concave, convex, single through multiple finger indent handles, and variations on the standard Jian handle shifting the widest point forward or backward.

TIP: Some instructors dislike ergonomic handles because they wish to honor tradition.

The Jian-style straight handle on many luxury-grade antique Butterfly Swords has some ergonomic characteristics. There is a belly that fits either the cup of your fingers or results in a slant towards the blade that pushes your hand to a tight placement against the D Guard. The flower motif landscape carving on a lot of the luxury grade antique knives is the ancient equivalent of the modern pistol grip checker. The biggest drawback of a straight handle is the need to bend the wrist to an extreme when stabbing.

The ergonomic characteristics of a Jian-type handle can be improved by adjusting its spine and belly to more closely conform to the hand. This should also increase ease of retention.

There is a beautiful example of a revolver shaped ergonomic 2-in-1 handle on an antique Butterfly Sword, though unusual handles on surviving knives are rare. Angling the handle down on a slope increases wrist comfort and power when thrusting due to the more natural alignment of the wrist and inherent placement of the hand and forearm behind the blade. It also increases torque on slices and chops. Greater torque results in more speed and thus more rotational kinetic energy at impact or, in non-physics, terms, more power. The downside of an angled handle is the shorter range of motion on a reverse cut, which would be relevant only if your knife had a sharp swage like on certain Red Boat knives.

These angled handles were made illegal in Hong Kong during Ip Man’s time because the knives were too deadly due to the extra power. They hit the main-stream again when EWC offered Modell Design’s famous Integral Knives for sale in the U.S.A. in 2010. Buick Yip also makes BJD with an angled handle.

There are a lot of potential handle shapes for Butterfly Swords. Ideally the handle is designed for the use and the specific practitioner, a feature of full custom Hudiedao. Some of the handle shapes are versatile and will work with most users. Others, such as grips with multiple single finger indentations, need to be fitted rather precisely to the owner’s hand taking into account whether a tactical glove will be worn. They are therefore inappropriate for even a limited production run.

Handle Materials

Handle Material: Type of handle material used.

There are a variety of traditional and modern materials used for handles on Hudiedao.

“Butterfly sword handles were traditionally made out of hardwood, horn, or wood wrapped with leather or cord. Wood is a traditional, classic choice and the standard for normal knife handles. Wood is comfortable, warm, easy to obtain and carve, and – depending on the variety – can have a lot of cachet. An appropriate wood – a beautiful hardwood (hard for durability and retention of fine details) with a fine grain – can produce an excellent grip. Woods do, however, absorb moisture (and oils), and are impacted by temperature changes. Horn is also a good traditional handle material, but it is porous, requires care and not suitable for all combat environments. Leather wrap is an excellent handle treatment if done right. Unfortunately if the wrong tanning method is used, the leather can get slippery. Modern Hudiedao tend to use a greater variety of materials, mostly to reduce production expense. Some very expensive modern custom Hudiedao use artificially stabilized wood that is highly resistant to moisture, expansion and contraction.”

Jeffrey Modell, History and Design of Butterfly Swords, Kung Fu Tai Chi magazine pp.64-65 (April 2010).

The critical requirements for a handle are that it stay solidly in place and provide for a firm, comfortable grip. You may have experienced a sword handle that begins to move around or rattle on a product manufactured in China. In some cases that is simply poor design – protruding screws and nuts come loose, wraps come undone – or bad workmanship. In other cases it is a bad choice of materials.

Most inexpensive woods used for imported sword handles are materially affected by humidity-induced expansion and contraction that becomes irksome in a Western environment. A few hardwoods such as Arizona Desert Ironwood and Cocobolo are naturally resinous and stable. Many beautiful non-resinous woods can be artificially stabilized by injecting them with resin under pressure. Most of the good looking naturally or artificially stabilized woods are expensive, but colored stabilized plywood products, such as Dymondwood® and Pakkawood, are affordable. Technically it is “Fused Phenolic Thermoset Resin-Impregnated Layers of Select Dyed Veneer Wood.” This material is better than ordinary wood for kitchen knives because there are fewer cavities for microbes. It takes a great polish that adheres well to the hand. The latter point is important. Jeff has a pair of slim line swords with natural wood handles so dry it requires extra effort to keep a stable grip.

A few years back Jeff placed two full tang Modell Design Porthau Bread knives in the trunk of his car for several days during a very cold Michigan Winter. One knife had very high quality resinous ebony handle scales, a gorgeous pricey wood but not in the league with presentation grade Ironwood. The other had the laminate. Shrinkage of handle scales on full tang knives is part of the price for having the strongest possible tang and highly unlikely to be a functional problem. If the single-piece handle of a hidden tang knife shrinks away from the D Guard so the handle is no longer firmly in place, that is serious. Anyway, the ebony should have cracked but it was so good it just contracted a bit. The less expensive laminate scales contracted less.

TIP: EWC believes stabilized laminate scales offer the best combination of quality and value for BJD.

Some martial artists in Hong Kong prefer metal handles to minimize the expansion and contraction. You can find these in aluminum, brass and soft steel. Steel handles actually can be comfortable.

Modell Design believes the best material for tactical knife handles is Micarta™, a brand-name that has become synonymous with phenolic generics made the same way. The material consists of layers of canvas, linen, paper, fiberglass or carbon fiber molded together under high pressure in thermosetting plastic. It is highly resistant to environmental impacts and hard, tough material. Jeff prefers the canvas and linen substrates since the matrix is exposed during grinding and facilitates a good grip. The layered paper phenolics polish up the best and adhere well to the bare hand but are slippery versus a gloved hand and show scratches. The fiberglass substrate is worrisome since after a bit of wear and tear loose glass fiber ends may float into someone’s lungs. Carbon fiber is the latest Western knife maker rage, and rather expensive. It looks best if left in relatively flat panel form which makes it difficult to shape a handle in three dimensions.

The phenolics tend to be a bit more expensive than common sword handle wood and stabilized laminated wood products. While readily available in the U.S.A., the developed world and China, they are harder to come by in some of the other locales with good sword forges. Knife collectors tend to snub phenolics, preferring Ironwood, Cocobolo or stabilized wood. They also dislike the stabilized laminates.

TIP: Knife collectors and Butterfly Sword users have different priorities.

This video is Parts 6 and 9 of 10 on Choosing Butterfly Swords by Jeffrey Modell. You might want to review Video 4 in chapter 4 as well, since it discussed Tangs. This video goes along with the blog article, but does not follow the exact same order of topics. We apologize that the AUDIO is OUT OF SYNC. This is the way the camera filmed the footage, so there is little we can do about it (simple aligning will not work). We hope you get some benefit, regardless:

[youtube]http://youtu.be/zrrgSWYqO1c[/youtube]

[youtube]http://youtu.be/juKlwFDV8sg[/youtube]

Ready for more? Go here to check out everything you need to know about D-Guards, Quillons, Knucklebows.

2 thoughts on “Choosing Wing Chun Butterfly Swords – Part 5 – Tangs/Handles”