This post is intended to to help you decide which series/model of Wing Chun Butterfly Swords to purchase. This guide is intended to be used for Everything Wing Chun’s (EWC) line of Butterfly swords, although it may have some value to you as a general guide (just keep in mind that because EWC only makes high quality swords, most of the steels, construction methods, and designs discussed won’t be found on other swords currently on the market, especially the standard Asian manufacturer’s swords).

Please note there is also a more detailed 9-part article on the swords available on our blog here. If you want more details on Butterfly Swords for Wing Chun, please check it out.

You can find all these Limited Edition swords and more at Everything Wing Chun’s Butterfly Swords Page.

The Series/Lines/Models of Swords:

Our sword making methodology is different. Instead of making 500 swords of 1 model in a cheap Asian Factory, we decided to only make 5-10 swords per model in a family run forge and offer a wide rage of options from you to choose from. This is a bit more expensive but gives you a LOT more options as well as a higher quality hand-made weapon to own.

It is our strong belief that EWC’s swords are the best you can buy outside of full custom swords – and they are always an incredible deal for the price. (If you need full custom work, we handle that as well.)

Currently, as of Dec 2012, Everything Wing Chun (EWC) has produced four main series of swords, in addition to 5-6 custom production runs. When you add up all the models, you have over 100 different swords to choose from. Not only that, but we have a que of about 30 swords ready for production, most with 4-5 variations – so another 100+ swords to choose from (coming soon!). This is an incredible amount of swords and nothing like this has ever been done before. Sorting between all the models can be confusing; this guide will help you determine which swords are right for you.

This guide covers the following series/lines/models of swords:

– EWC Integral Swords (Limited Edition, Sold Out)

– EWC Flagship Line (Limited Edition)

– “Tough-As-Hell” Editions of all Lines (Limited Edition)

– EWC Premium Line

– EWC Premium Line, Economy Training

– EWC Tomb Warrior Line

– MasterPath Domination Line

– It also applies to most of our Custom Work in terms of Steels, Grinds, Blade Types, etc.

The Details of our Butterfly Sword Listings:

On each sword page you will find a table that lists the specs for that particular model. This is the detailed description of what you will find on that table. The table looks like this:

Series: List the series the sword belongs to.

Blade Style: Refers to blade shape.

Blade Length: Approx. length of actual blade from base to tip.

Blade Steel: Type of steel the blade is made from.

Blade Grind: Type of grind used on the blade edge.

Blade Sharpness: How blunt or sharp the blade is.

Blade Finish: Type of finish used on the blade.

Blade Ricasso/Choil: If the blades use either of these design elements.

Blade Fuller: If these blades have a blood groove.

Blade Tapers: Type of tapers used on the blade.

Tang: Type of tang used on the sword.

D-Guard Metal: Type of metal used for the guard.

Knuckle-Bow: Shape/style of the knuckle-bow.

Handle Material: Type of handle material used.

Handle Alignment: Angle/alignment of handle.

Handle Shape: How the handle is shaped.

Handle Type: Refers to if the swords are full handles, have slim hands, or are 2-in-1.

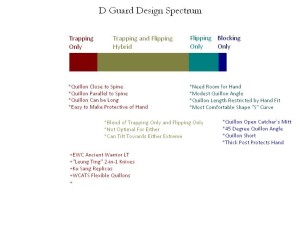

Flipping vs Trapping: Refers to the Quillon and if it is made for flipping or trapping.

General Comments and Fit:

All Swords Are Made With Superior Construction Techniques – Historically Chinese Butterfly Knives actually used for combat relied on a quality hidden tang and a carbon blade. We offer these hidden tangs on our Premium Models, but have also taken it to the next level with a far stronger full tang on our Flagship and Tomb Warrior lines. (Compare both of these methods to everything else currently on the market which uses modern corner cutting method of using a shorter piece of steel for the blade and welding a thin strip or screw on to it to serve as the tang (a rat tail tang)). Our handle scales are triple pinned (or screwed) and glued to the full tang. The D Guard is hot drop forged (drop forging is used to make hammers). The blade is carefully fitted to the D Guard so the weapon is solid. The blade is sent out by the forge partner for professional expert heat treatment (heat treatment is of critical importance — better an adequate steel with a good heat treatment than a great steel with a poor heat treatment). The 9260 blades are finished with a power-coat to help protect the blade from the air, which will cause this quality steel to rust. All of these methods are unique to EWC’s construction process and is what separates our swords from most of the garbage to be found on the market today.

The Fit – The other key component, that most martial artists are not sophisticated enough to know about, is the fit. The blade fits through the front of the D Guard (the hilt) perfectly, a true custom fit worthy of $3,500 swords. You won’t see this on any of the other production models out there because it is too difficult and expensive to do. This means a lot to designers, sword enthusiasts and knife folks. To knowledgeable folks these swords would go for a much higher price because they recognize the value and will pay for what martial artists cannot afford. You are getting this craftsman ship at a price that is ideal for you as a martial artist.

Series/Line of Swords:

The first step is to determine which series/line of sword you want. These are the main characteristics/highlights of each:

Integral Line – Each knife in this series was hot drop forged from a single piece of steel (the D Guard is integral to the blade) and the handle scales are triple-pinned and glued to a full tang. The balance is sweet. These professional-grade butterfly swords were part of a limited edition run of only 50 pairs, and sold out fast!

Flagship Line – After the release of our Integral swords we spent 6 additional months gathering feedback from top over 30 sifus and improving the design. These swords are the result of that work. They are lighter, quicker, stronger, feel better, and trap better than the Integral swords, which were already the best swords on the market. The balance on these swords is second-to-none. The major difference between these and the Integral model was in the design of the quillon and D-Guard. In order to facilitate better trapping, flipping ability has to be sacrificed some – so the Integral swords flip easier and these trap better. These, however, still flip much easier than any other sword on the market – make no mistake they trap and flip very well. In addition the blade shapes have been modified to better suit multiple lineage’s requirements.

The flagship line is our full tang weapon-grade line of swords. The best steels and the best construction methods are used. The balance, fit and finish are extraordinary. They sport ergonomic and angled handles; a hot-drop-forged D-Guards in ASAI 304 stainless steel; a quillon designed for flipping and trapping. The blades have distal and profile tapers (not a flat piece of steel) and sport either an true lenticular or wide hollow grind. The swords have full handles, not half handles.

Tough-As-Hell Models (All Series) – These models are the same as their parent series, except we use a high quality hammered 9260 carbon spring steel for the blade. It is the toughest steel for blade vs blade contact that we found. Wing Chun masters of old would be mighty jealous of these blades. The blunt models sport a wide rounded lenticular grind edge to hold up vs hard training. The sharp models are ready for full combat. These blades are all coated black to reduce glare and protect the steel from rust.

Premium Line – This is a (small) step down from the Flagship line. The main differences are 1) Lower Price 2) The tang is a full hidden tang that runs inside the handle 3) We use a straight handle, not an angled handle. Otherwise they are the same high-quality swords as the flagship line.

Premium Line Tough-As-Hell – See Tough-As-Hell Models (All Series)

Premium Line, Economy Training – This line follows the Premium Line models, but are solid aluminum swords and also feature true 2-in-1 models. These are a really great as well as affordable. The swords are solid and hold up in hard training. (We do not recommend it, but have hacked wood and broken cinder blocks with these swords during our testing – they held up well!)

Tomb Warrior Line – This line of swords is based around the D-Guard found in an ancient Wing Chun warrior’s tomb in China. We know the swords are from a Wing Chun man due to the “Baat Jarm Dao” inscription on the swords as well as a manual found with them. While the information and pictures of the tomb’s contents remain a Chinese state secret that will only be released many years from now, we have gotten confirmation of their existence.

The only real difference in this line compared to the Flagship/Premium lines is the D-Guard shape, the fact they have 1/2 handles to fit together better in 1 hand and use a Trapping-Only quillon. The D-Guards on this line are more square and have a spike on the bottom edge to prevent blocked weapons from slipping under your sword and hitting you. They also make your punches a lot more penetrating.

Those that are familiar with the WingTsun lineage swords might notice that the D-Guard is very similar to those used by Leung Ting’s lineage. In fact, Grandmaster Ting based his design around the same ancient warrior’s swords. They are not his original invention. Many WingTsun practitioners will really love our models of this sword.

Tomb Warrior Line, Tough-As-Hell Edition – See Tough-As-Hell Models (All Series)

DOMINATION Line – The Domination line swords are true combat-grade weapons. They feature full exposed tangs, cord wrapped handles, powerful squared D-Guards, perfect balance, straight handles, flipping and trapping ability, top-grade weapon steels, and a variety of blade options. These swords are combat-weight and not for the weak or timid. If you need a sword to Dominate your foe, then this is the choice for you. Only a limited number of each model will be made.

In June 2014 we put out a survey asking Sifus and Senior students what they wanted in a butterfly sword. We got over 160 replies from Sifus. The DOMINATION line of swords is the first result of that survey. (Yes, we are making other models based off of the answers). We heard that you and your Sifus wanted more straight-handle sword options with a squared D-Guard. Done. You wanted more blade length options. You now can select from 11-14 inch blades. You wanted a true American full-tang (exposed tang) sword that was made from D2 or 440C. Done. You wanted full-handles, and a quillon for trapping and flipping. Done and done. You wanted more room in the D-Guard for your fingers in reverse grip. Done. In addition we made sure the squared D-Guard was based on historical models. We then widened the front and flattened it a little so you could actually do push-ups on the swords (holding the handles, blade edge facing down without touching). Don’t actually do this, it is dangerous – but that gives you a great blocking surface that also helps prevent an opponent’s weapon from slipping under your guard. These guards are great for training bashing movements into wooden training dummies. And along those lines, the handles are also cord-wrapped so you never slip when training.

We’ve handled maybe 150 pairs of butterfly swords over the past 3 years. We were trying to find a name for this new line, but coming up empty. Then the first swords arrived from the forge. When we picked it up we realized this was an awesome weapon. The sword was a 13″ D2 chopper, and it could easily take an arm off an opponent. It was then we got the name “Domination” – because if you wield these weapons that is what you will do to your opponent. For those wanting light and fast weapons these are not for you (we’ll get to you next). These swords are for those that simply want to destroy their opponent. They are combat weight and can take the full force of a blow from a crowbar (a common weapon home-intruders carry) and keep on going. The Sharp D2 Lenticular grind versions are much heftier than the 440C hollow-grind versions, so choose accordingly.

Custom Swords – We do a couple custom projects a month. Many have the same features as the above series. If you see them offered for sale, they will follow the same format as the rest in terms of listing what is what.

Blade Style:

After you know which series fits your needs, then it is time to determine which blade you want. We are offering multiple blade styles because each lineage has different requirements:

The Bellied Chopper is mainly used for hacking and slashing techniques. It makes the chops very powerful and a real weapon can can cleave through bone. Choppers sacrifice the ability to stab effectively. Our chopper resulted from our careful study of the best features of the blades on Ip Man’s actual swords and other famous Sifus, added to world-class experience.

The Hybrid Blade is our own invention. It is a mix of a pure chopper and a stabber. We felt that even though most lineages use the modern chopper version, you still need to be able to stab effectively, so we made the blade in a manner that allows it to effectively chop and stab. This allows all lineages to use the swords. Most chopping versions of the swords are too blunt and rounded at the tip to stab effectively, while most stabbing versions are too thin and not rounded enough to chop. This version allows you to use the swords in all methods of attack: chopping, stabbing, slicing and slashing.

The Narrowing Stabber is mainly used for piercing opponents. The narrower blade and sharper tip facilitate this. These blades are good for stabbing and slicing, but sacrifice some chopping ability. You will notice that the top edge of the blade (the spine) is also angled downward. This give the sword more piercing power as the tip is in alignment with the handle and wrist. This is very similar to how they made the swords in the Red Boat (war) era of Wing Chun’s history. These are lighter and faster than the choppers. Our 12″ stabber was based on a historical triangular design rather than using one of the ugly modern rectangles that had no precedent in historical China (and are just a low cost manufacturing innovation).

The Straight-Edge Stabber is used by a few lineages. Instead of narrowing, the edge of the blade and spine run parallel to each other, until the end of the sword when the tip rounds up. Stabbing ability here is lost to gain a little chopping/blocking ability. This is more of a lineage specific design rather than a historical one, but one that is quiet popular.

Blade Length:

Blade lengths were primarily determined by our surveys. Each lineage measures the blade differently. Historically each blade was custom made to the practitioner, but that is not possible outside of full custom swords.

Your Sifu should be able to tell you the correct length for your lineage. Typically one will measure from one of three spots. 1) Outside wrist to outside elbow (covers entire forearm), 2) Inside wrist to inside elbow (best for those that flip inside the arm), OR 3) Pocket of thumb joint to inside elbow (a mix of the previous two).

The <= 12 inch blade length is good for the lineages that flip the swords to the inside of their arms in the Guan Sao and Quan Sao movements. With longer blades they would either cut their opposite arm or have to open their elbows too much, thus give up valuable time and power generation in the movements. This 12″ blade length is actually close to the longest traditional length for Wing Chun. This shorter version of the blade is rooted in the Red Boat days, when the swords had to be tucked into a boot for concealment. The Moy Yat, Leung Ting, as well as many other lineages and smaller Wing Chun practitioners tend to use blades in this range.

The 13 inch blades were made for specific lineages that require a 13″ blade, as some historical chopper designs were this length. Ip Man’s own swords were about this length for example. Typically the Choppers are 13″. The Ip Man/Chun/Ching, Wong Shun Leung, Koo Sang and other popular lineages commonly use this length on their blades.

The >= 14 inch blades are mostly from the pre-Wing Chun era and are used in other Southern Shaolin styles. They can only be used on the outside of the forearm and go all the way past the elbow on most people under 6 feet tall. They also prevent many common Wing Chun techniques from being properly executed, but that is really something that is lineage specific. If your lineage measures the blade from the wrist to the outside of the elbow, then these are for you. The William Chung lineage, for example, is one of the few that that likes these longer blades.

Blade Steel:

Are you doing Weapon vs Weapon training, do you have the ability to oil your swords, do you only display them or use them for light pole and air training? Determining use will help determine what steel to choose. The stainless steels are better for maintenance and carbon steels best for contact. For an in-depth discussion of steel used on modern Butterfly Swords please read Modell Design, LLC’s article The “Best Steel” for Chinese Butterfly Knives on this blog. In order of toughness, we offer the following:

420 Surgical Stainless – This steel is very common – a lot of production butterfly swords are made from it (If a sword says “Stainless Steel” you can bet 99% of the time it is a cheap 420 stainless.). The 420 we use is of a higher quality, but it is still a stainless that is best suited for light training, display, or air training. The benefit of this steel is the low maintenance required. You don’t really have to worry about rust with 420. It is great if you just want a great looking pair of swords and don’t plan on hitting other weapons or using them for real. We typically do not carry sharp versions of 420 stainless because it is not a weapon-grade steel. 420 is okay vs training vs wing chun long poles.

440C Stainless – This is really the cream-of-the-crop when it comes to stainless steels. Do not confuse it with other stainless steels used on modern butterfly swords, which are usually a softer, cheaper version of stainless (cheap versions of 420). 440C is the toughest stainless there is, and we used only the best German made steels. 440C is a high-chromium steel with a terrific balance between hardness and corrosion resistance. 440C takes a nice edge and is fairly easy to resharpen if you desire to do so. If you are buying these swords for display, forms training, or pole vs swords work then 440C is ideal. 440C is the favorite stainless steel many custom knife makers, including the top U.S. custom knife maker Jay Fisher and Mark Waite, a top quality U.S. knife maker with expertise crafting fine custom Butterfly Swords. Everything Wing Chun and Modell Design, LLC were the first to make production run Butterfly Swords in 440C.

D2 Tool Steel – This is a extraordinarily tough and hard steel which offers good corrosion resistance and excellent mileage in wear resistance. It is able to take and retain a very fine edge (though unlike 440C it is a pain to sharpen and resharpen). It is considered by a number of top Western custom knife makers to be the best carbon steel for blades. It is a good choice for hard use applications. D2 is often used to cut other steels. D2 is very hard to work with when making swords. It has taken our forge an extra 6 months of work to make these blades in large part due to the trouble of shaping such a tough steel. D2 is considered semi-stainless and will not rust as quickly as other high-carbon steels, however care will need to be taken to prevent rust. (See the article Combating Rust on Swords on this blog for more details). Pick D2 if you want to do hard-core training and can keep the blades clean and waxed after use. The sharpened D2 blades are not to be used in training. Everything Wing Chun is the first to make Butterfly swords in D2 Tool Steel.

Hammered 9260 Carbon Spring Steel– This is a real combat steel. Unlike what is commonly called “Combat Steel” from other manufacturers (which is usually a cheap flat piece of 1050-1065 carbon steel), this steel and method of forging is considered the cream of the crop by top sword and katana makers around the world. Many knife collectors prefer the high carbon steels for their resilience and feel it is well worth the intensive maintenance. In our tests this steel was the best steel for hard hitting use (D2 was also an excellent steel, BTW, and requires less care). The blades are flexible enough not to break when stressed and hard enough not to dent easily. Unfortunately due to the high carbon content of these blades they rust easily. For that reason all of our blades are power-coated with a black finish. This will help prevent rust. Otherwise one would have to oil these blades after each use. Important Note: On the full tang versions of swords in 9260 you will see the steel that runs through the handle the metal is exposed to air. This means you need to be careful and wipe your tang off after each use and apply a wax or oil to the metal regularly, especially when storing them. (See the article Combating Rust on Swords on this blog for more details).

No matter how tough the steel, we NEVER recommend any sword for weapon vs weapon training because ALL weapons fail at some point and can cause massive injury. While these are D2 and 9260 steels make very capable blades, NEVER go steel on steel with your swords.

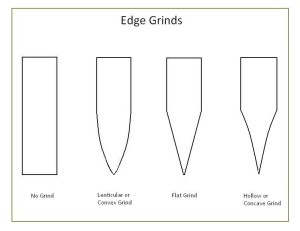

Blade Grinds:

The grind of a blade refers to how the cutting edge is shaped.

Hollow Grind – These blades have a wide, attractive hollow grind, with a deep functional fuller – labor intensive design elements normally found only on expensive, custom made swords. This grind is best for sword vs flesh applications in real life, but we use it because we think it makes the swords look great. This grind is not good for sword edge vs sword edge because the thinner edge can dent – similar to the way a razor is good for cutting but not blocking.

Lenticular Grind – This is a historical grind that is best for weapon vs weapon contact because it has extra steel behind the blade. The blunt versions are ideal for hard training applications. The sharpened versions are not AS sharp as the hollow-grind swords, but are extremely sharp and functional.

Lenticular Grind with Hollow Bevel – A sharp observer will note that all Tough-As-Hell Edition blades look like the actually have hollow-grinds, not lenticular. We made the swords like this on purpose. We think a hollow grind looks better and a lenticular grind functions better. So we have combined the two in a unique manner ideal for training or real combat.

Blade Sharpness:

Blunt – Although the tip is pointed, the blunt models have a 1 mm or 2 mm rounded edge depending on the model and use (the thicker edge is more for training models). This edge usually cannot be sharpened without a grinding wheel and someone with experience sharpening swords. The reason being that the blunt sword is designed for training and you don’t want a thin edge if you are hitting wood, metal or training partners.

Sharp – On the sharpened models the blade has been sharpened to a fine sharp edge (it is not razor sharp, but will cut very well). Please refer to your local laws on the legality of owning sharpened blades in your area.

Blade Finishes:

Satin: The blades are made with a non-reflective stain finish. While not quite as good as a glossy finish for maintenance, satin is better for the swords that are to be photographed or filmed by Sifus making books/videos. They also don’t show fingerprints as easily and do not reflect light as much.

Black Powder Coating: We powder-coat blades to protect them from the air and thus from rusting. The swords are powder coated in 350 degree heat to add the black finish. This finish is not 100% ideal for training swords because with hard use or with weapon vs weapon contact the power coat will chip. However, All coatings eventually wear off but the coating is a head start on reduced maintenance. Please keep an eye on the powder coating of your sword as it is the sword’s protection against the elements. Exposed to air the blade would start to rust and have to be oiled after each use.

Glossy: After being forged, swords are hand-ground, tempered and polished to a glossy*, limited production grade finish.

*A note on mirror finishes: 440C, especially this good German quality, will take an absolutely perfect mirror finish. We don’t intend to do it on these $900 per pair knives; we do expect very fine scratching; thus the “glossy” finish. Custom knife maker Mark Waite can do a perfect mirror finish for about $3,800 a pair. Real mirror finishing is about a twelve step process and a main reason why true US made custom blades are so expensive. It goes through a progression of grits, and if any one is imperfect (one scratch) the entire polish process has to repeat from that step. It requires an American or European sense of quality control to detect it at the end of that step. These swords use about three or four steps. A lot of Western full custom knife makers put a satin finish on their knives (a “hand rubbed finish”) to save the expense of a serious polishing job, and these are full custom priced knives each a fraction of the size of one of our blades. You should be able to see your reflection, but not a bathroom mirror reflection – rather a reflection as though looking in a piece of glossy steel.

Blade Ricasso/Choil:

Ricasso: A Ricasso is the un-sharpend, un-tapered portion of the blade near the base of the D-Guard. Ricasso make sharpening sword easier, but some people like the edge to goal the way to the D-Guard. Almost all our swords come with a Ricasso. It creates a stronger stop point if your opponent’s weapon slides down the edge of your sword to stop at the intersection of the edge and D-Guard. On knives it can be gripped to help facilitate blade removable or fine work. Some folks may be tempted to risk a pinky there during a reverse grip.

Choil: Unsharpened and indented portion as the base of the blade. Advantages: Basically the same as a Ricasso. It just gives an indent for a finger to go if you ever want to put one there. Aesthetics.

Both a Ricasso and a Choil are non-traditional.

Blade Fuller (a.k.a. Blood Groove):

Full Fullers: There is a deep, functional fuller (aka ‘blood groove’) on the each side of each blade. A fuller helps impart rigidity to the blade, lighten it and make it easier for the target to bleed out. Contrary to popular belief, it is not to stop a vacuum from keeping the blade stuck in an opponent. Throughout history, swords have been made with no fuller, a fuller on one side, a fuller on both sides, or more than one fuller per side. They did not see much use on ordinary Chinese butterfly swords, but we think the feature adds to the aesthetic of the design and improves the blade.

Decorative Fuller: The blade sports a thin cut into the blade that is really only there for looks. More typical on thinner blades and is non-functional.

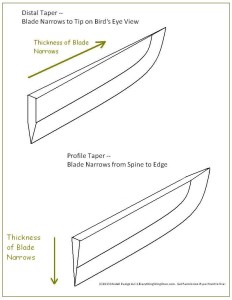

Blade Taper:

A taper turns a flat piece of steel into a elegant sword with proper balance. EWC is currently the only company offering tapers on production swords. Profile and distal tapers have been added to all blades for balance and function.

A taper turns a flat piece of steel into a elegant sword with proper balance. EWC is currently the only company offering tapers on production swords. Profile and distal tapers have been added to all blades for balance and function.

Blades can narrow from the spine on top to the edge (i.e., the cross section thins as you near the edge) or from the handle as you approach the tip. These tapers modify the weight, point of balance and handling characteristics of individual weapons. Traditional Butterfly Swords exhibited both of these tapers (called a profile taper and distal taper, respectively), but for cost reasons modern Butterfly Swords tend to have a flat piece of steel for the blade with perhaps a small ground area near the edge to sharpen it. Some modern swords are so poorly designed that no amount of tapering can rescue them.

Advantages: Weight, balance, handling, tradition.

Disadvantages: Cost. Not possible on thin blades. Involves hand workmanship and can result in some variation between swords in a pair.

Tang:

Tang refers to the way the handle is attached to the blade, and specifically the type/amount of metal coming off the blade and going into the handle. We only offer the best in terms of Tang, no corners are cut. Your blade will never come lose or rattle. There are only 2 ways to make a sword properly, and EWC is the only one currently offering true full tangs on all their swords:

Full Tang: These are true full tang swords. The handle and the blade are one solid piece. It is impossible for the blade to ever become loose (a very common thing with all of the other swords on the market). You can actually see the tang sandwiched between the wood of the handle – so you know for sure you are getting what you paid for. Most “full tang” swords are only a partial tang and/or only have a very thin strip of metal in the handle. This is a professional full bodied full tang sword.

Hidden Full Tang: These are historically accurate full tang swords where the tang is 100% hidden in the handle. All of our hidden tang swords have a thick piece of steel as the tang – no corners were cut just because the tang is hidden from view. This is a historically accurate way to make combat butterfly swords.

D-Guard Metals:

304 ASAI Stainless Steel – The D Guard is a separate piece of hot drop forged AISI 304 stainless steel. The folks who make expensive custom Western knives cut a corner and use 416 because, even though 304 is better, it is very tough to work with. We cut no corners. We went through a ton of prototypes getting the D guard just right.

Brass – We sometimes use Brass for the D-Guards. While not as tough as 304, It is a quality metal and more historically accurate (real butterfly swords often had brass D-Guards). Brass sometimes looks a lot better, but it also tarnishes and the golden hue will turn brown over time if you don’t keep the brass polished.

Gold Plated – On some models we are now offering gold plated D-Guards over Brass. These should not be used for training as the softer gold can come off under stress. This option is only available on sharpened swords and really adds a touch of class.

Knuckle Bow:

Flagship/Premium Line Knuckle Bow: The knuckle-bow has been designed to be a slim line protective fit that is good for all hand sizes and can withstand heavy blows from incoming weapons. We managed to retain a knuckle-bow curve for additional strength during defense or bashing. High quality AISI 304 steel was used.

Tomb Warrior Line Knuckle Bow: The design comes from a sword found in an ancient tomb. The square knuckle-bow sports a spike at the bottom edge. Both of these features help prevent an opponent’s weapon from slipping under your guard after you block. The spike also adds a deadly element to your punches.

Handle Material:

Stabilized Wood – The handle is made from stabilized wood and is pinned (or screwed) and glued to a full tang, so it will not crack or warp over time. Most inexpensive woods used for imported sword handles are affected by humidity-induced expansion and contraction. This stabilized wood product is far more resistant.

At this time we are only offering special woods on custom projects.

Handle Angle/Alignment:

Angled Handle: The handle is angled down to accommodate both versions of use – chopping and stabbing – as well as to facilitate use in the reverse grip effectively and comfortably. This is pretty unique, and EWC was the first to offer swords with a handle angled, followed by Buick Yip. These ergonomic handles were actually made illegal in Hong Kong during Ip Man’s time due to the extra power one could generate with the sword. This design increases power and comfort for thrusting due to alignment of the wrist. This is also more comfortable for chopping strikes, and provides greater speed and torque resulting in increased power.

Straight Handle: The straight handles swords are more common and many people prefer them because they were trained to use them and/or have certain techniques that are better executed with the straight handles.

Alignment: Alignment refers to where the handle is in regards to the tip or the spine of the blade. We only offer professional real weapon alignements. Many modern production butterfly swords have handles in the middle of the blades out of alignment with the tip. In 99% of the cases this is completely wrong, historically incorrect, and functionally incorrect. It is a product of sloppy modern manufacturing. (There is one exception for swords designed to strike armor, but it is a special case and not seen in modern production). Most of the time the handle should align with the tip for thrusting power. The handle needs to be near the spine for flipping ability and chopping power. Almost all of our swords align the handle with the tip and spine. We only comment on alignment on swords that have a unique positioning.

Handle Shape:

While the exact shape will vary from time to time, the handles are typically ergonomically designed to be comfortable and reduce the odds of slippage. We go through a lot of designs and prototypes before finalizing the carefully shaped design. All handles are comfortable and a hand-friendly design. If the handle design is common enough to have a name, it wil be mentioned here.

Handle Type:

Full Handles: Each sword has a full handle instead of a half handle because in this day and age having a better grip on the sword during training and/or combat is more important than slipping both swords into one sheath or holding both swords in one hand. The full handle feels better to use and causes less training accidents. While it is a full-sized handle rather than a slim-line or 2-in-1 you can still sheath two knives next to each other (but be careful not to scrape and scratch the handles).

Advantages: These allow for the best blades and handles possible. Full Grips allow for highest level of comfort as well as best control (and less chance of losing control of a blade). Best for actual combat.

Disadvantages: Hard to hold both blades in one hand and will not fit into one sheath. May be an issue at the start of the form.

Slim Handles: These handles and slimmer than the full handles, but are still complete handles, as opposed to the half-handles in the 2-in-1 models. We only make these by request.

Advantages: These can support a full blade, be held in one hand, and fit into one sheath together.

Disadvantages: Less comfortable than a full handle, less control than a full handle, and it is not as easy to fight with two swords in one hand as with the true 2-in-1 models.

2-in-1 Handles: These handles fit together so the blades fit together and can be held in one hand. 1/2 the handle is rounded, 1/2 the handle is completely flat (on the inside. This is very common in Wing Chun and historically. Unfortunately many people do not like 2-in-1 handles for training or real combat since they are more uncomfortable and unwieldy. One must decide if they want good full handles or the ability to sheath, draw, and hold both swords together easily. Advantages and Disadvantages are the same as the Slim Handles, except these are even more difficult/costly to produce as 2 molds are needed.

Flipping vs Trapping (Quillon):

The quillon is the part of the D-Guard that comes up on the back side of the sword for trapping an opponent’s weapon or flipping your sword. There is always a trade-off between flipping ability and trapping ability. The more you can do of one, the less you can do of another.

Our Flagship and Premium lines have a quillon that is a great balance of trapping AND flipping ability. It took a long time and many prototypes to develop and get just right for most people.

Flipping/Trapping: These swords are also excellent in flipping ability. They just naturally flip back and forth smoothly, due to the balance and quillion design. This is something you do not find normally, and especially not on swords with a quillon designed to trap weapons. We went through a lot of prototypes trying to get this balance of flipping and trapping just right, and we think you will be pleased with the outcome.

Flipping Only: This quillon is designed you facilitate easy switching from normal grip to reverse grip on the sword. The ability to flip is second to none, but the ability to trap an opponents weapon is sacrificed.

Trapping Only: This quillon was designed to trap and secure and enemy weapon. This makes it very hard to impossible to flip the sword and hold it in a reverse grip. But the trapping ability is second to none – you will likely damage anything you trap. Be careful with poles and swords you trap – your training partner might not like their stuff messed up!

Conclusion

I hope this guide helps you in your quest to find your Ultimate Butterfly Sword. A special thanks goes out to Modell Design, LLC, our exclusive Wing Chun Butterfly Sword design partner; as well as our forge. Much of the research and many of the innovations you see on our swords are a result of Modell Design’s research and commitment to quality. If you want to tap into our world-class design team, please contact us about our Custom Wing Chun Swords Program.